Right now the world is facing a major shortage of various computer chips, critical components that are at the heart of many modern day products, including Instafloss. Industry analysts are even going so far as to call it Chipaggedon. So what is it and how does it affect Instafloss?

What is Chipaggedon

Chipaggedon is a shortage in electronics components of all kinds, but most severely in chipsets. It began with COVID related effects causing supply and work shortages as well as unexpected demand shifts, but now was just made worse when the snow storms and rolling blackouts in Texas shut down many of the semiconductor manufacturing plants.

Even if you’ve never heard of Chipaggedon, chances are you’ve already been affected by it. The first signs of this shortage affected the gaming industry where graphics cards and the newest Xbox and Playstation consoles still remain hard to get. But, it’s not just affecting gaming. Car manufacturers are being forced to cut production of new vehicles by as much as 40%, and unfortunately many other sectors, including our own, are feeling the impacts now as well.

Chipaggedon and Instafloss: Will There be Delays?

The short answer:

Yes. At this time we’re hoping it will only be a couple of weeks.

The long answer:

We’ve just been informed that the microprocessor we originally planned to use in Instafloss is facing a 6 month backorder. This came as a huge shock to our team and we’ve instantly scrambled to address the issue, pursuing multiple angles to get the components we need to assemble instafloss.

Right now, we’re announcing a 2-week delay only as we’ve got two different options which would enable us to bypass that 6-month backorder:

- Purchasing chips from the secondary market which has them stockpiled

- Looking into redesigning for a similar performance chipset which is more readily available

We’re hopeful that one of these will pan out and enable us to deliver on time with minimal delay. However, the potential for greater delay is there and we’ll have a better idea in next month’s update exactly what things are looking like.

Other Manufacturing Updates

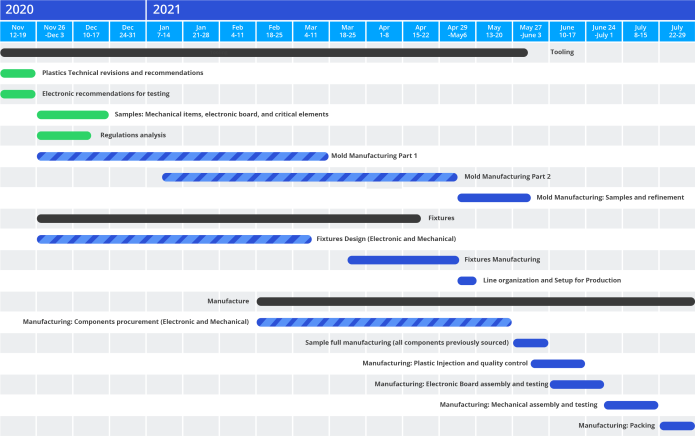

One of the biggest changes to our manufacturing timeline is a direct result of the above, but is actually a positive change. We’ve begun Components Procurement (Electronic AND Mechanical) now instead of waiting until April to do so. This should help us avoid any other issues related to limited component supply as we’re able to build a stockpile sooner rather than later.

Another, minor change, is that we’re not officially closing out the Fixtures Manufacturing task, and pushing back tooling in general. This adds room to redesign both the unit and the molds/fixtures should we find a microprocessor that is readily available, but requires minor alterations to the design.

Why would we need to alter the design and thus molds? Well, as part of the packaging of all the parts, the central ‘chassis’ of the Instafloss is designed with clearance for the control board. If the processor requires a major redesign of the control board, certain parts would move around, requiring us to change the clearances on the chassis. However, we do not anticipate this major of an issue. But we also don’t want to say something is done, then take it back later.

As always, thank you for your support and we’re working diligently to minimize any delay from this worldwide shortage.

Keep Smiling,

Team Instafloss

0 comments