The supply chain shortages that manufacturers are facing right now have been compared to the Great Toilet Paper scare of 2020 but on an “epic” scale. Individual components are out of stock with huge (51+ week) lead times, and those that have stockpiles are either keeping them for themselves or selling the components at massive premiums.

In turn, manufacturers are panic buying what they can as they rapidly search for solutions to this unprecedented dilemma.

As a new company bringing our product to life during these challenging times, we’ve found a pretty big silver lining: We’re able to adapt and take this time as a lesson for the future.

This particular shortage may be temporary, but the ways that we as a company are adapting our team and product will help protect us from potential future supply chain disruptions.

Designing Instafloss for Components Modularity

Traditionally, when you design a product, you pick the set of components that make the most sense and design it only around those components. When we created the Instafloss prototype and first set of designs for manufacturing this was the case.

However, the component shortages we faced have forced us to re-evaluate that position. Some of you may remember in a previous update that we floated the idea of redesigning the Instafloss to accept alternative components so as to avoid waiting lengthy delays on the components we originally designed for.

At this time, we’ve gone a step further by designing Instafloss to be modular and capable of accepting multiple different components so as to avoid disruptions both present and future. Due to strict performance requirements of the Instafloss this involves a lot of stress testing to ensure there are alternatives which meet our strict requirements without compromising on quality/durability.

We have had a lot of engineering success in this process. In some cases, like with our PCB’s DC to DC converter (used to reduce the voltage coming into the unit), we have the ability to accept 3 different components!

Many times we can only pick between two alternatives, but even this is miles ahead of what is traditionally done where products are designed to use one set of parts and that’s it.

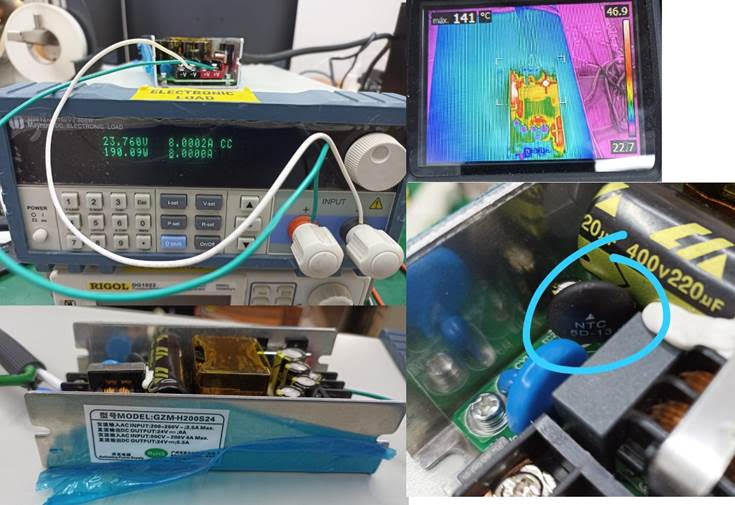

As you're reading this, testing continues on an alternative for the Power Supply to give us some added redundancy and resiliency in that area as well.

As you can see, the two models of power supply vary in their exterior design. Luckily, Instafloss was designed for the larger of the two first, making retrofitting the smaller PSU easier if it passes out strict stress testing regimen.

Of course, from the consumer perspective, there will be zero difference between any Instafloss unit. This is just to assure, as much as possible, that no matter what shortages there may be in the future, we are unlikely to go out of stock ever again.Despite Our Best Efforts, Not All Components Have Alternatives

Unfortunately, there are some cases where an alternative is impossible to source. This is the case with a component that’s proving to be the biggest current determination of our delivery timeline: the motor control bridge driver. This component is necessary to control the Instafloss’ motor and without it, you would not be able to adjust the Instafloss’ pressure.

The design for our control board is based around this chip and even though we could redesign the board, there is no suitable alternative to this driver. This is resulting in a lot of pent up demand with the lead time on new orders for these chips being quoted as 51+ weeks.

We foresaw this demand and had the foresight to order these components much sooner than you typically would, but even with our best efforts we’re running into delays. Our order was originally meant to deliver in April, but as we mentioned in a previous update was pushed back to August. Now they’ve pushed back the delivery timeline to mid-September.

This is currently the only bottleneck for our manufacturing with all other processes proceeding according to plan, and it’s extremely frustrating for us as a team as there’s nothing we can do but wait for our order to be fulfilled in order to fulfill your orders!

Given the current timeline for delivery on that component, we are targeting a Q4 delivery for all preorders, with Batch 1 being ready and shipped first, of course.

As you see in this post, that isn’t stopping us from using the time we have to make Instafloss better (as explained above), and going forward, we will plan to stockpile this component so we can avoid potential shortages in the future.

As always, thanks for helping us bring Instafloss, and thus our vision of healthier gums to reality. We’ll continue to keep you updated in future month’s updates.

0 comments